DSJH GSJH Series RADIALLY SPLIT BETWEEN-BEARINGS CENTRIFUGAL PUMP

DSJH series are single stage double suction horizontal radial split case centrifugal pumps and GSJH series are two stages single/double suction horizontal radial split case centrifugal pumps, designed and manufactured completely in accordance with API610 11th Edition BB2 for a guaranteed service life of min. 30 years and 3 years of continuous trouble-free operation.

Product Description

Overview

DSJH series are single stage double suction horizontal radial split case centrifugal pumps and GSJH series are two stages single/double suction horizontal radial split case centrifugal pumps, designed and manufactured completely in accordance with API610 11th Edition BB2 for a guaranteed service life of min. 30 years and 3 years of continuous trouble-free operation. Both DSJH and GSJH are center line support structure designed for heavy duty petrochemical process application.

These series of pumps are designed and developed with compact structure, high efficiency and reliability featured with long service life and convenient maintenance, suitable for most severe and heavy working conditions.

Specifications

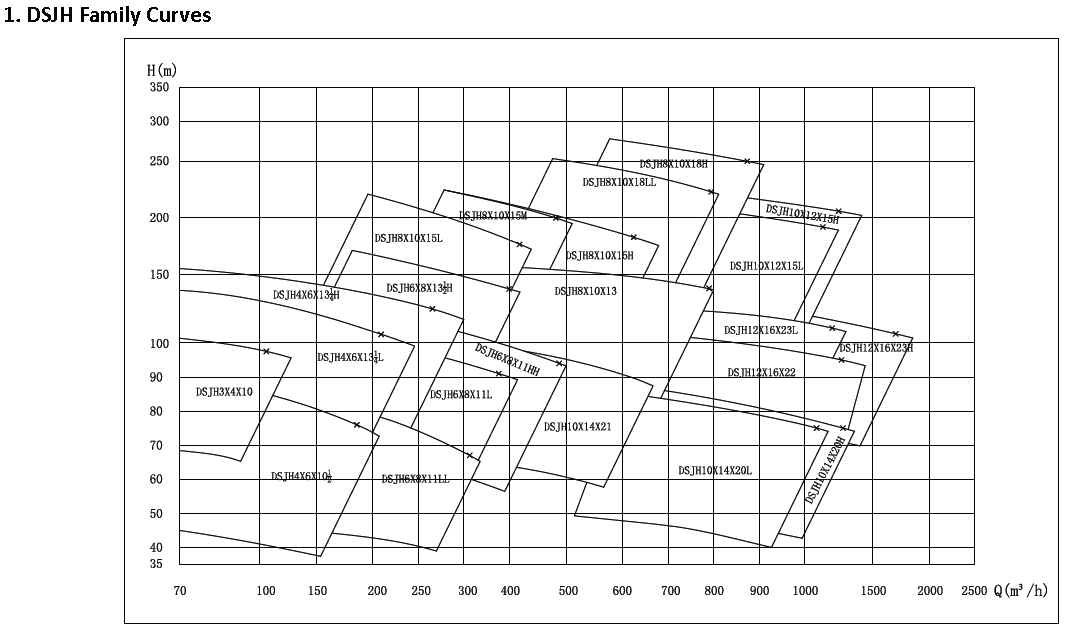

Single stage (DSJH)

Flow rate: Q = 84 ~ 1700m3/h

Disch. head: H = 65 ~ 250m

Working pressure: 5MPa

Applicable media temperature: T = -80℃ ~ +450℃

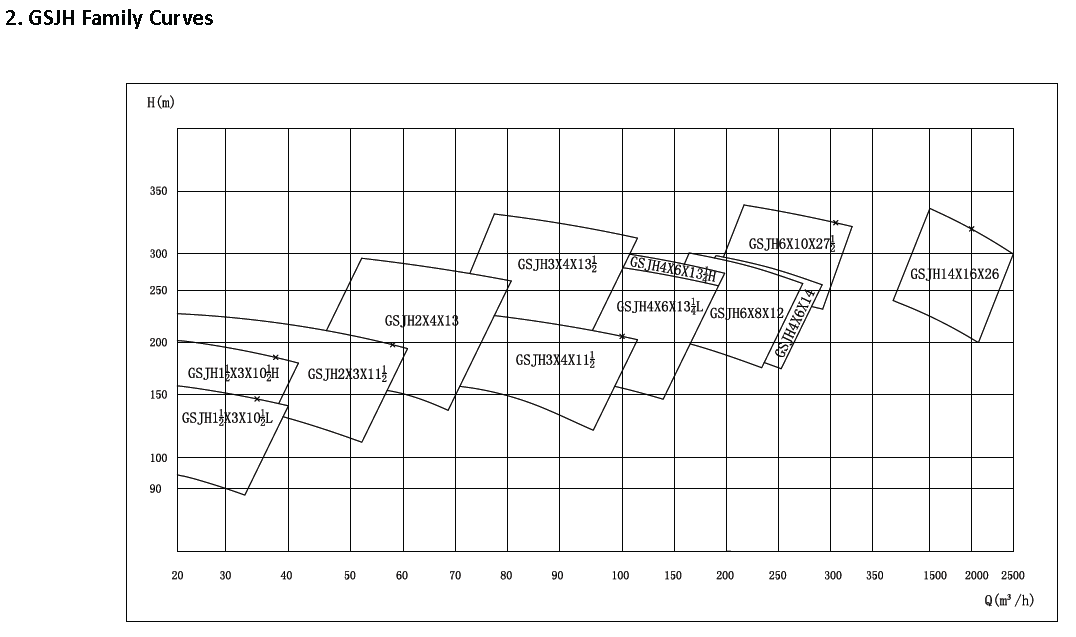

Double stage(GSJH)

Flow rate: Q = 35 ~ 2000m3/h

Disch. head: H = 140 ~ 335m

Working pressure: 11MPa

Applicable media temperature: T = -80℃ ~ +450℃

Applicable media: crude oil, refined oil products, petrochemical products for petroleum refining, petrochemical products and similar clean or corrosive chemical liquids with solid particles.

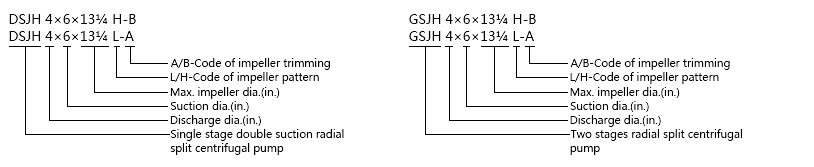

Model Description

Structural Features

DSJH is of single stage double suction between bearing structure while GSJH is of two stages single/double suction between bearing structure

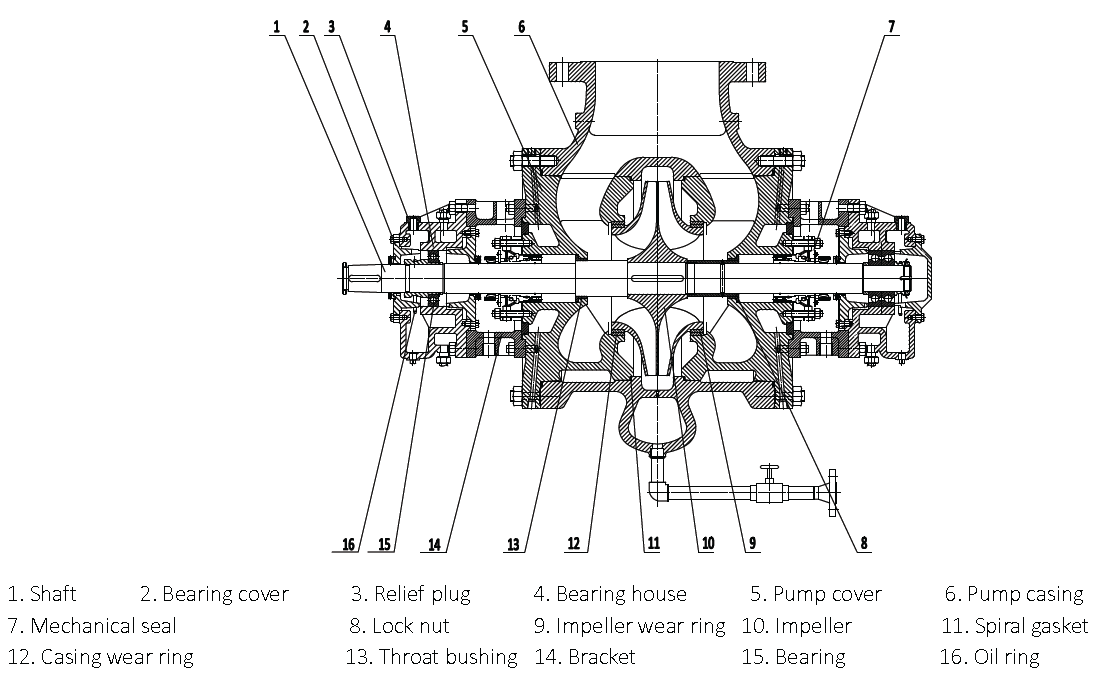

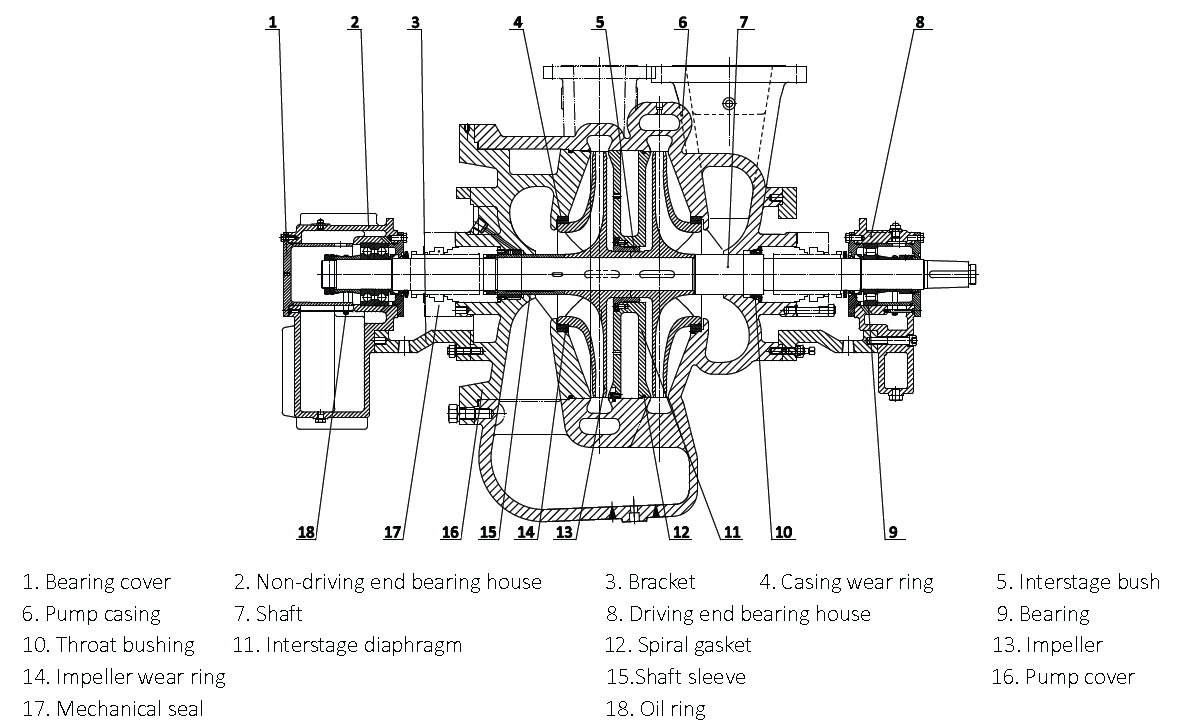

1.Pump casing

The pump casing is designed for high pressure up to 5MPa and 11MPa. It can be improved to deliver higher pressure media as may be required.

Pump casing of radial split and center line support structure, which is especially suitable for delivery high temperature, high pressure, inflammable, explosive or toxic liquid, guarantees an uniform and minimum casing deformation when temperature of pump casing changes.

Pump casing for high discharge head is designed with double volute structure to balance radial force; meanwhile, flow channels in the first and second stage pump casing of GSJH series are in 180° opposite arrangement to balance radial force.

Suction chamber is designed in half spiral shape to increase the pre-rotation and improve the anti-cavitation performance.

Double-suction impeller is designed with impeller vanes at both sides in uniform alternative arrangement so as to change the frequency of liquid passing through the impeller and eliminate noise and back flow. In other words, it is such a lowfrequency hydraulic design that pump performance range and efficiency are intrinsically ensured.

Each seal surface in the flow channels shall be sealed by spiral wound gaskets to ensure reliable sealing without leakage

under high temperature and high pressure conditions.

Pressure reducing cavity, designed prior the seal chamber at the high pressure end of double stage pump, shall be connected with the suction inlet through the balance pipeline so as to obtain a balanced pressure between both seal chambers.

Suction inlet and discharge outlet are casted as one piece with pump casing both in vertical upward arrangement, which make it possible for wear parts and wear-resistant parts to be easily replaced without disturbing the motor as well as suction & discharge pipelines. Flange dimensions and pressure rating conform to ANSI16.5 or other standard as customer requirements.

Reliable heat tracing system or API610 cooling system is designed to deliver high temperature liquids or heat tracing liquids.

2. Impeller

Hydraulic performance for each pump is based on the optimized design output from advanced design software, CFX fluid simulation analysis plus prototype model verification tests with a very wide operation zone.

Impeller is precisely casted to guarantee accurate design pattern and high efficiency.

Single and double suction impellers are optional for the first stage impeller of GSJH double stage pump according to cavitation performance requirement.

3. Rotor

Rotor is of between bearing structure with sufficient shaft margin and heavy duty rigid shaft design.

All parts and accessories installed on the shaft are subject to dynamic balance as the rotor assembly to ensure reliable and smooth pump operation with minimum vibration.

Pump shaft is made of superior alloy steel as a minimum requirement and the coupling side is designed as per API610 in conical shape for the convenience of mounting and disassembling of coupling, bearing and mechanical seal.

4. Bearings, Lubrication & Cooling

There are 3 types of bearing arrangements, namely, rolling-element radial and thrust, hydrodynamic radial and rolling-element thrust, or hydrodynamic radial and thrust. In any case, the basic rated service life for each type shall be at least 25,000 hours on rated operation conditions.

There are 2 types of bearing lubrication: the first one is that bearing housing is designed with increased capacity to ensure perfect oil lubrication at high speed continuous operation running at least 25,000h without the need of changing any bearing; the second one is that bearing housing is designed with forced lubrication from external oil depot to maintain reliable lubrication.

Bearing housing is designed with heat dissipation fins and cooling fans may also be equipped if necessary so as to ensure excellent bearing cooling; it is mounted with constant level oiler for automatic supplement in time in case of lubricating oil consumption.

Forced lubrication from external oil depot is designed as per API614.

PT temperature transmitters are designed to detect the temperature rise of bearings.

Cross Section Drawings

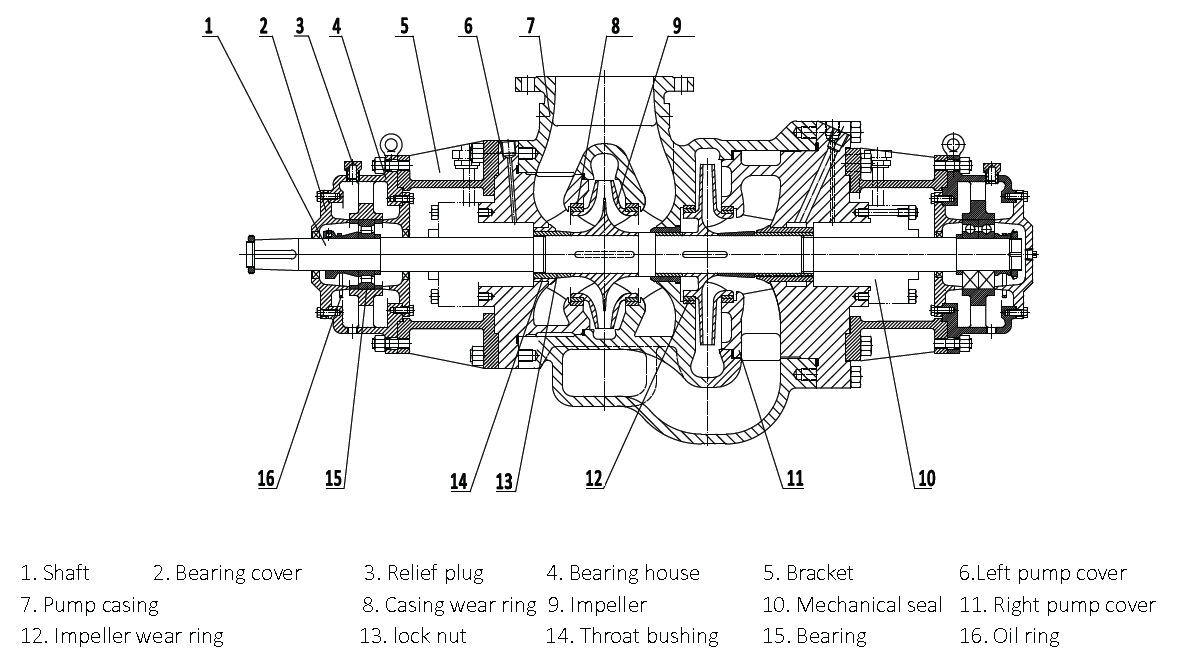

1. DSJH single stage double suction centrifugal pump

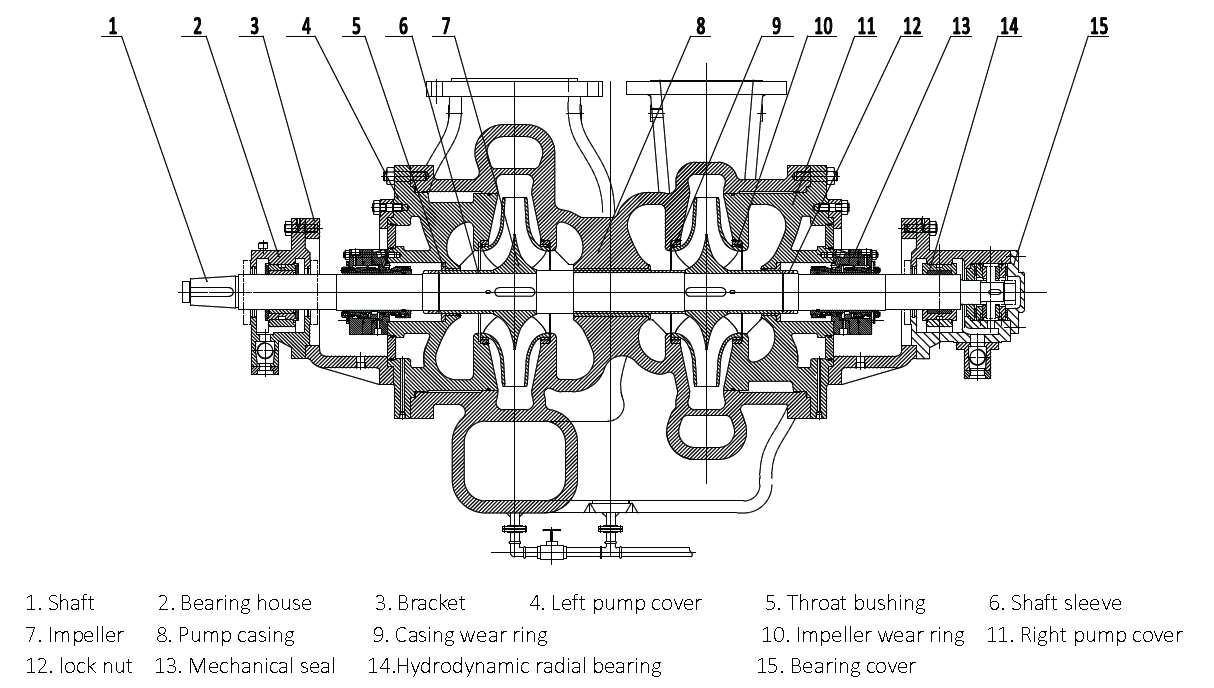

2. GSJH two-stages centrifugal pump

3. GSJH two-stages first stage double-suction cenrifugal pump

4. GSJH two-stages double-suction cenrifugal pump

DSJH/GSJH Series Family Curves

Previous Page

Related Products