VSD Series SINGLE STAGE DOUBLE SUCTION SPLITCASE CENTRIFUGAL PUMP

VSD series single stage double suction axial split casing horizontal foot mounted or center line mounted centrifugal pump are API BB1 pumps designed and manufactured completely in accordance with API610 and ISO13709.

Product Description

Overview

VSD series single stage double suction axial split casing horizontal foot mounted or center line mounted centrifugal pump are API BB1 pumps designed and manufactured completely in accordance with API610 and ISO13709. On basis of advanced technologies introduced from domestic & international leading players in the same field, VSD series BB1 pump is a new generation of product with high efficiency and energy conservation developed from CFX fluid simulation analysis plus prototype model verification tests. Tandem and parallel operations are allowed as may be required.

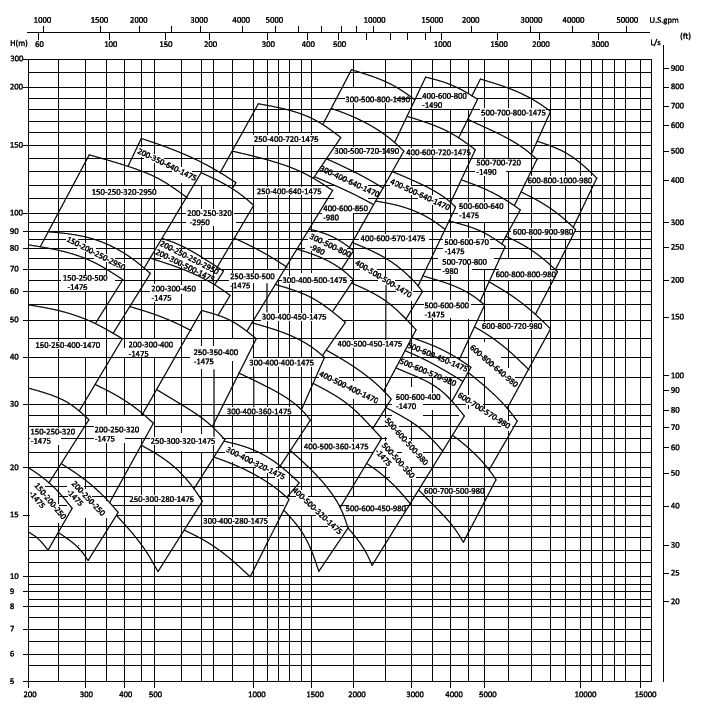

Specifications

Size: DN = φ125 ~ φ800 mm

Flow Rate: Up to 10000 m3/h

Disch. Head: Up to 220 m

Pump Speed: 980/1480/2980r/min

Working Pressure: 0.4 ~ 6.4 MPa

Working Temp.: -20 ~ +200℃

Applicable media: oil (crude oil or refined oil) for oil processing & refining, petrochemical engineering, chemical industry, natural gas industry and other industry; process liquid with slight particles; media of similar physical and chemical property for other industries.

Model Description

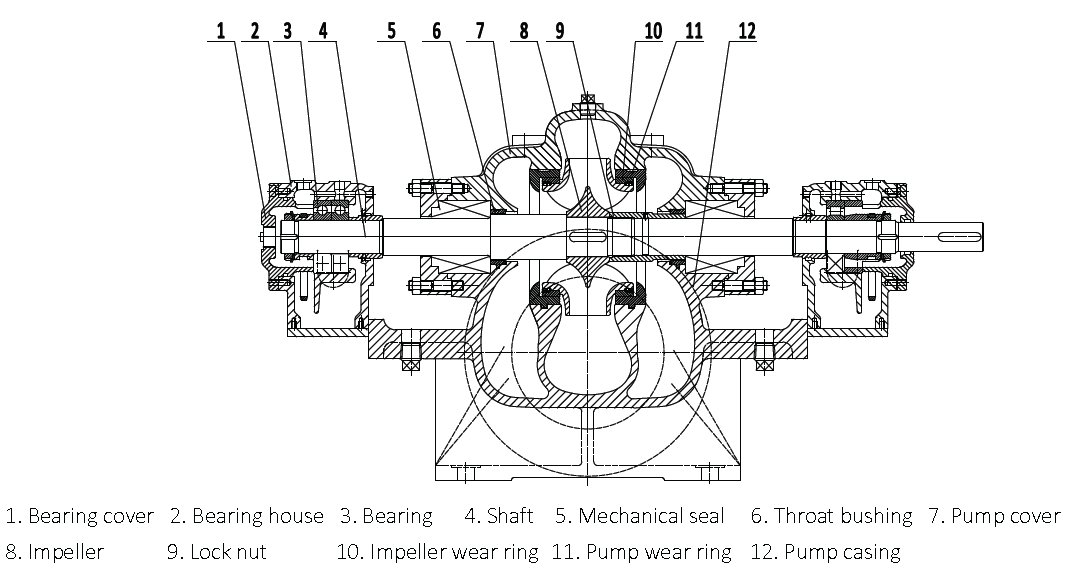

Structural Features

VSD series are horizontal split-case, between bearings, axially split, single stage, double suction, foot mounted or centerline mounted centrifugal pumps.

1. Pump Casing

VSD series are double suction axially split volute type centrifugal pumps.

Pump casing is of axial split case structure, both suction inlet and discharge outlet are located at the cower and it only needs to lift the rotor after opening the pump cover for maintenance without removing pipelines and driving motor.

Pump pressure chamber is designed as double volute structure to balance the radial force, remove or reduce the alternating stress applied on rotor so as to improve the shaft fatigue and extend the pump service life.

Pump casings are designed with enhanced thickness for the contacting faces to guarantee an uniform and minimum casing deformation under high pressure working conditions.

Foot mounted or centerline mounted types are optional for different applicable media.

2. Impeller

Double suction impeller has enclosed passageway with replaceable wear ring, which is separated from casing components by casing wear ring.

Optimized vane dimension ensures high efficiency, low cavitation and low pressure fluctuation under stable operation in wide operation zone.

Impeller is of double suction structure to balance axial force.

Dynamic balance test on all impellers and rotors are carried out according to G2.5 of API610 so as to ensure stable operation and low vibration.

3. Bearings & Lubrication

Bearing housing is of axial split structure; the whole rotor can be removed after disassembling the pump cover and uppering bearing so as to facilitate maintenance and assembly of pump.

Journal ball bearing at shaft stretch end absorbs radial force; journal thrust ball bearing (mounted back to back) at the other end fixes the axial rotor position and absorbs the remaining liquid axial thrust.

Bearing housing is designed with increased capacity to ensure perfect oil lubrication at high speed continuous operation running at least 40,000h.

Bearing housing is designed with heat dissipation fins and cooling fans; cooling water may also be equipped through if necessary so as to ensure excellent bearing cooling.

Sectional Drawing

VSD Series Family Curves

Next Page

Related Products