VHGA Series VERTICAL IN-LINE SINGLE STAGE CENTRIFUGAL PUMP

Overview VHGA series vertical in-line single stage centrifugal pumps are API OH3 pumps designed and manufactured completely in accordance with API610 11th Edition. VHGA series are over-hung pumps with independent bearing bracket between motor and pump which are connected together through flexible coupling with spacer.

Product Description

Overview

VHGA series vertical in-line single stage centrifugal pumps are API OH3 pumps designed and manufactured completely in accordance with API610 11th Edition. VHGA series are over-hung pumps with independent bearing bracket between motor and pump which are connected together through flexible coupling with spacer. There will be no need of disturbing the motor when maintaining the mechanical seal and bearings after dismantling the rotor assembly. It is especially suitable for important application with relatively high temperature. Compared with horizontal pumps, vertical inline pumps are economic solution with compact design and simple for piping connections.

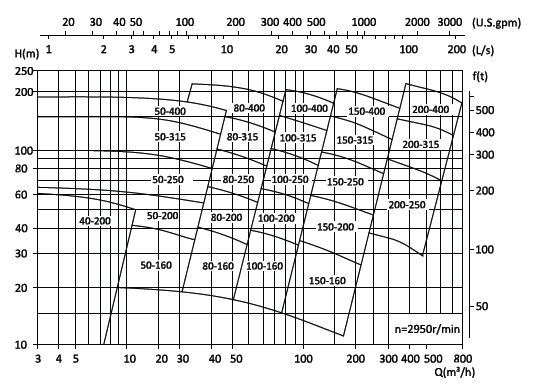

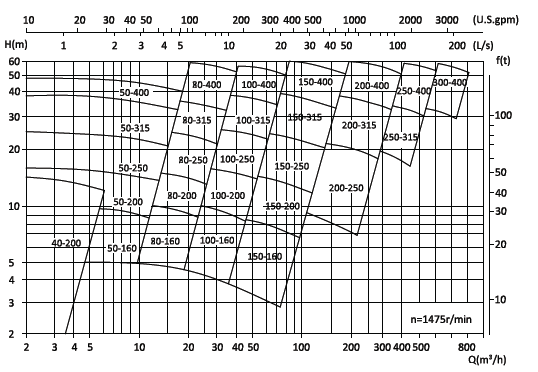

Performance Range

Flow Rate: Q = 3 ~ 700 m³/h

Disch. Head: H = 4 ~ 200m

Working Pressure: P = ~ 4Mpa

Working Temp. : t = -20 ~ 250℃

Applicable media: Petroleum, petrochemical products with slight particles for petroleum refinery, petroleum purification, petrochemical industry and chemical industry or similar liquids for other industries.

Model Description

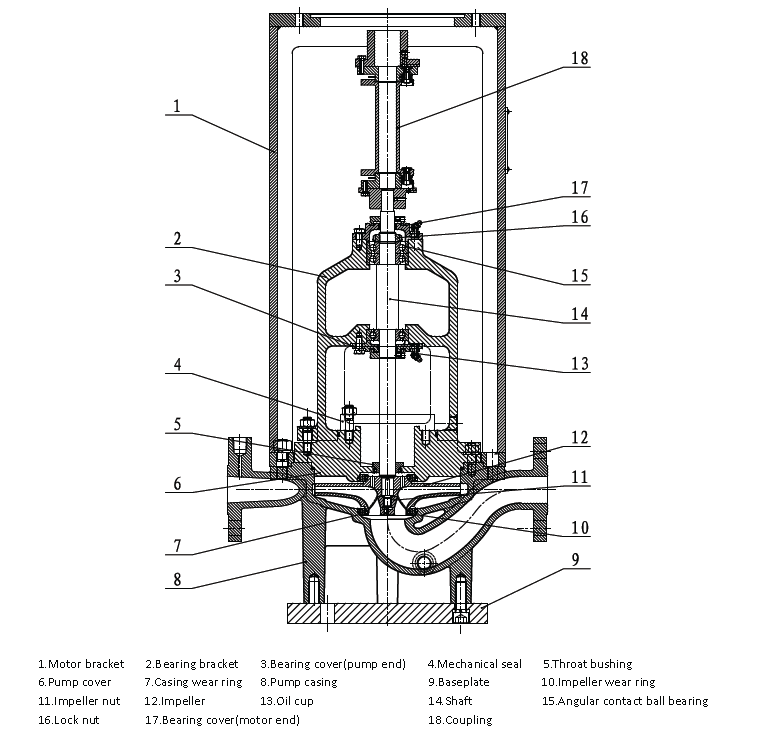

Pump Structure

1. Pump Casing

|

Pump casing is of radial split structure and spiral wound gasket shall be used for sealing between pump casing and cover. Pumps with nozzles more than 80mm are designed as double volute casing to balance the radial force and minimize pump vibration. Drain nozzle is designed on the pump casing and nozzles for pressure measuring and mechanic seal flushing are located on the suction & discharge flanges. Suction and discharge flanges are designed of the same size with the same pressure rating on the same axial line. GB, DIN, ANSI standards are available according to the pressure rating and customer requirements. Pump cover can be designed for heat insulation and cooling to facilitate pumping of temperature-sensitive media. Vent nozzle is located on pump cover. Back pullout design with independent bearing bracket between motor and pump which are connected together through flexible coupling with spacer. There will be no need of disturbing the motor when maintaining the mechanical seal, bearings and other wear parts after dismantling the rotor assembly. |

|

|

2. Impeller Single stage, single suction and closed impeller is keyed to shaft and secured by locknut and lockscrew to guarantee the mounting safety and reliability. The impeller is dynamically balanced to ensure smooth operation with less vibration. The impeller design is hydraulically optimized to improve cavitation performance and efficiency. |

|

3. Axial Force Balance

Axial force shall be balanced by the front & rear wear rings and balancing holes on the impeller.

Pairing angular contact rolling bearings are employed to absorb the residual axial thrust, rotor weight and transient load during pump startup.

Bearing is mounted within the bearing bracket and lubricated by grease.

|

4. Mechanical Seal API-682 cartridge mechanical seal & flushing systems with full options for leakage detection alarming and shutdown signals to ensure continuous failure-free long-term running in the most severe working environment. |

|

Cross Section Drawing

VHGA Series Family Curves

Related Products