VZ Series SINGLE STAGE END-SUCTION CENTRIFUGAL PUMP

VZA/VZE/VZF/VZU series single stage radialsplit casing back pullout centrifugal pumps are designed and manufactured completely in accordance with API610 11th Edition for a guaranteed service life of minimum 25 years and 3 years of continuous operation without any trouble.

Product Description

Overview

VZA/VZE/VZF/VZU series single stage radialsplit casing back pullout centrifugal pumps are designed and manufactured completely in accordance with API610 11th Edition for a guaranteed service life of minimum 25 years and 3 years of continuous operation without any trouble. VZA/VZE/VZF/VZU series in 54 models are the upgraded design with careful consideration of concerns and possible problems neglected from the earlier Editions, especially based on the past decades of operation experiences underdifferent environment and working conditions in terms of connection between pump casing and bearing bracket, mechanical seal, cooling methods and auxiliary pipeline. VZE/VZF/VZU series pumps are widely used in all kinds of industrial processes due to the brilliant features of high efficiencyand low NPSHr for high temperature and high pressure applications.

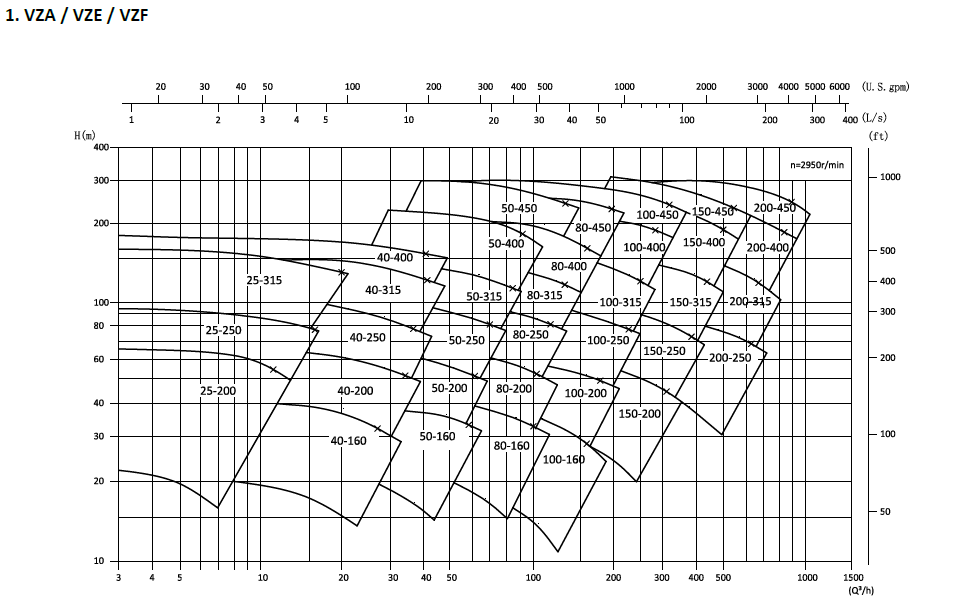

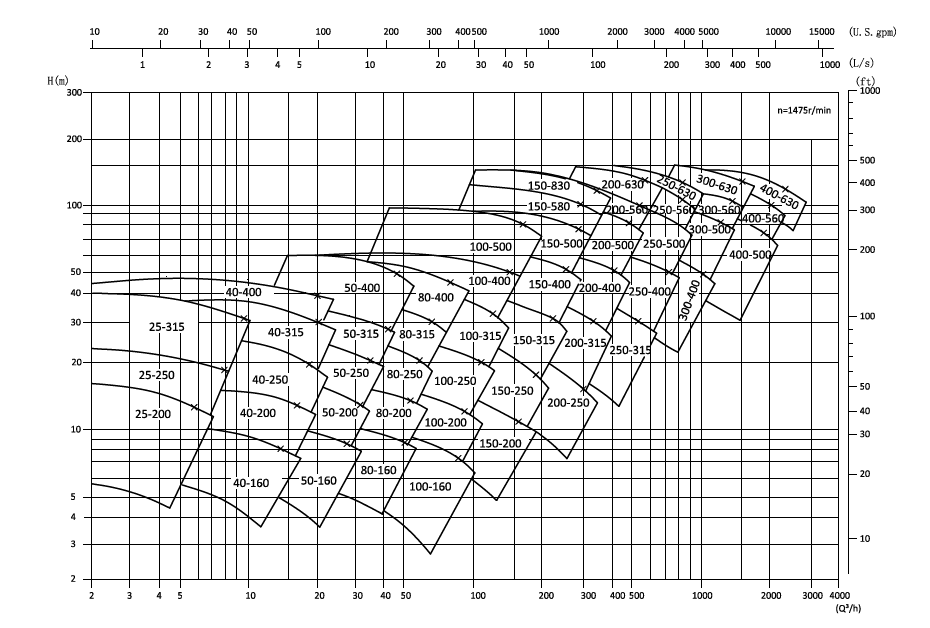

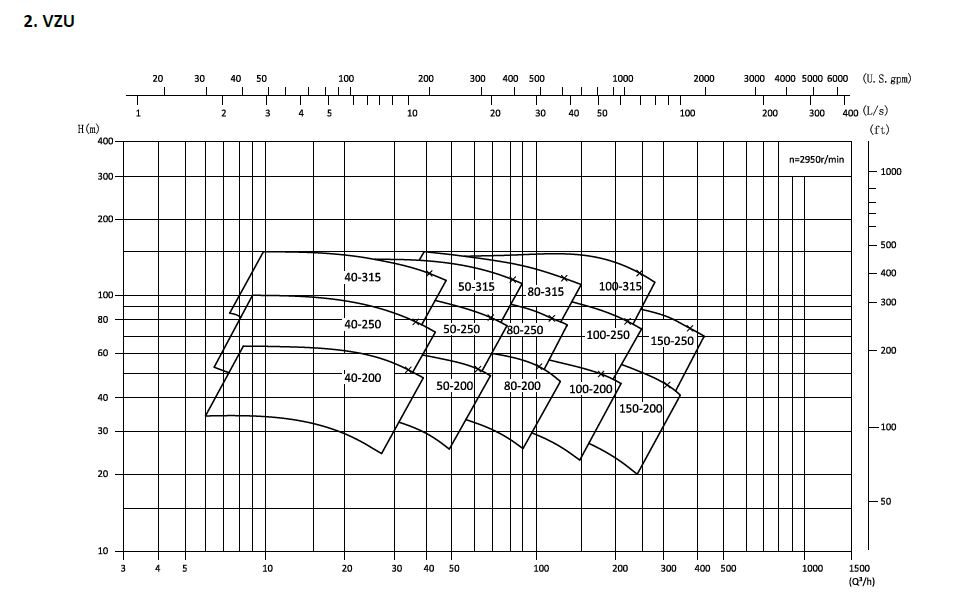

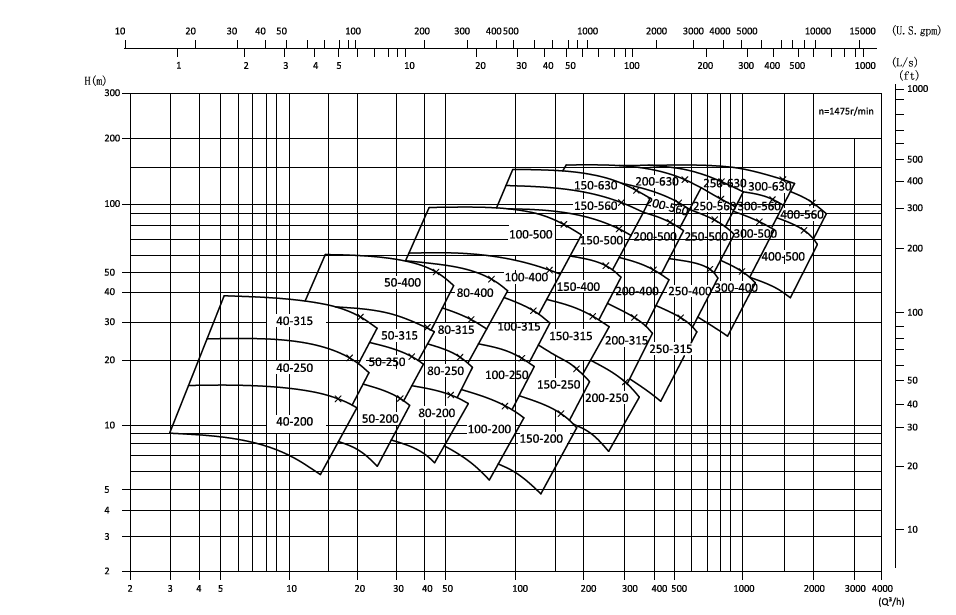

Performance Range

|

VZA Flow rate(Q): up to 2600 m3/h Disch. head (H): up to 300m Temp.(T): -80℃ ~ +300℃ Pressure(P): up to 5MPa |

VZE Flow rate(Q): up to 2600 m3/h Disch. head (H): up to 300m Temp.(T): -80℃ ~ +450℃ Pressure(P): up to 5MPa |

VZF Flow rate(Q): up to 2600 m3/h Disch. head (H): up to 250m Temp.(T): -80℃ ~ +450℃ Pressure(P): up to 7.5MPa |

VZU Flow rate(Q): up to 2000 m3/h Disch. head (H): up to 220m Temp.(T): ~ +450℃ Pressure(P): up to 13.5Mpa |

Applications

| ● Refinery | ● Petrochemical purification | ● Petrochemical industry |

| ● Coal processing | ● Cryoengineering | ● Oil transportation |

| ● Pulp & paper | ● Pharmacy | ● Environmental engineering |

| ● Water supply & heating | ● Sugar industry | ● Sea water desalination |

| ● Electric power engineering |

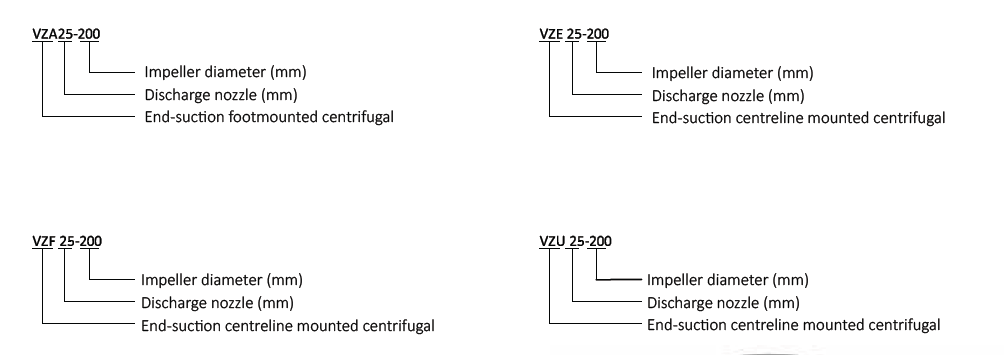

Model Description

Pump Structure

VZA/VZE/VZF/VZU series are single stage single suction horizontal split volute type chemical process pumps. VZA pump are foot mounted while VZE/VZF/VZU pump is centerline mounted. The same pressure rating has been applied in suction & discharge flanges with the feature of axial suction and tangential discharge at the top. Working pressure for VZA/VZE is up to 5MPa, VZF up to7.5 MPa and VZU up to13.5 MPa.

1. Pump Casing

Pump casing with disch. diameter larger than 80mm is designed as double volute structure to balance radial force;

It is equipped with replaceable pump casing wear rings which can be flushed as needed;

Pump casing and pump cover are sealed by spiral wound gasket.

2. Impeller

Optimized hydraulic performance design through software and CFX fluid simulation analysis plus prototype model test verification to ensure high efficiency and excellent cavitation performance at any applicable flow rate in a wide operation zone.

Open impeller is available as needs.

Impeller wear rings are replaceable.

|

|

|

3. Bearing Housing

Lubrication: large pressure angle duplex angular contact ball bearing (pressure angle is 40°) and deep groove ball bearing are alternatively used in the process of lubrication (combined used if under special working conditions); bearing housing is designed with increased capacity to ensure perfect oil lubrication.

Bearing housing is mounted with constant level oiler for automatic supplement in time in case of lubricating oil consumption.

There are three cooling ways used in bearing housing including heat dissipation fins for temperature of 120℃ , combination of heat dissipation fins and cooling fans for temperature of 120℃ -250℃ , finned tube oil cooler for the temperature of 250℃ above. In addition, PT100 temperature transmitter may be installed to detect the temperature rising.

4. Balancing Force

Pump casing with disch. diameter larger than 80mm is designed as double volute structure to balance radial force.

Suction chamber is designed with diverter to balance pre-rotation, improve

inlet conditions and suction performance.

Seal rings are mounted in the front & rear ends of impeller to balance axial force; axial force from balancing holes of impeller as well as residual axial force are absorbed by large pressure angle angular contact ball bearing.

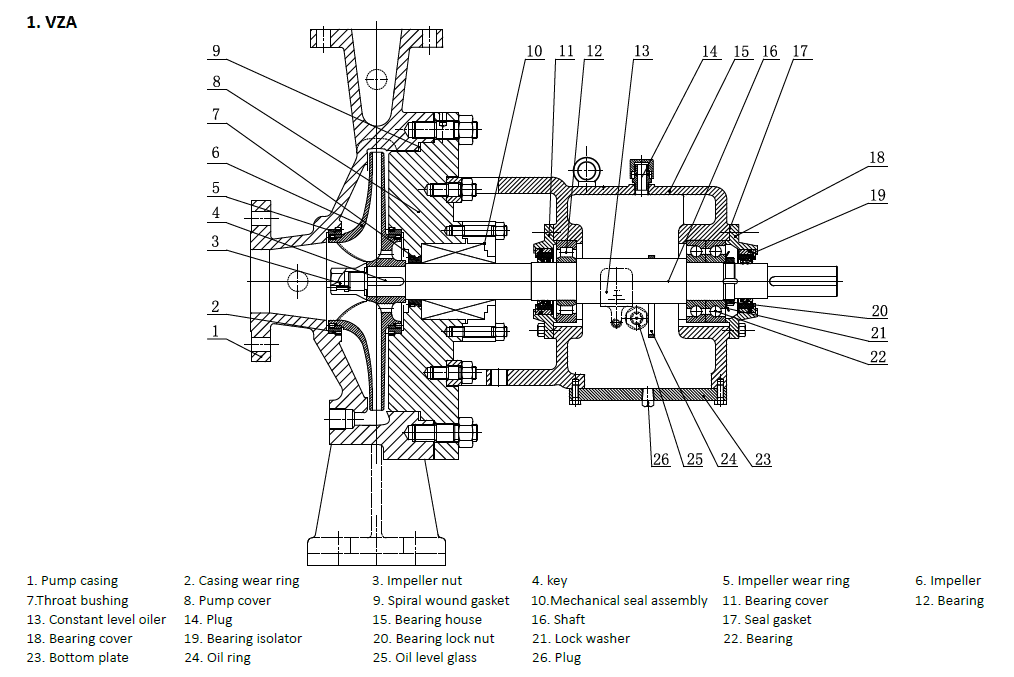

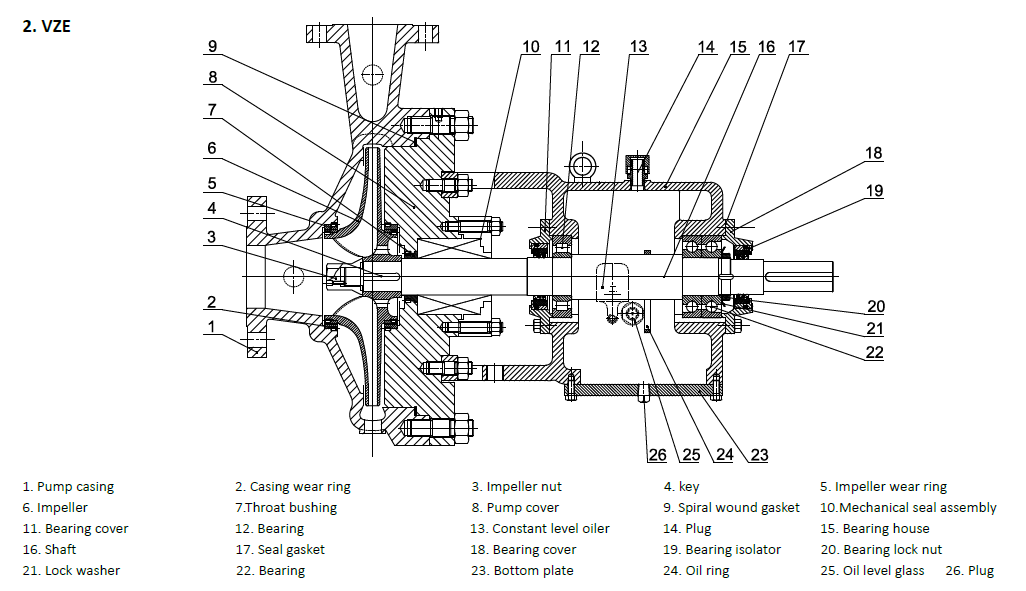

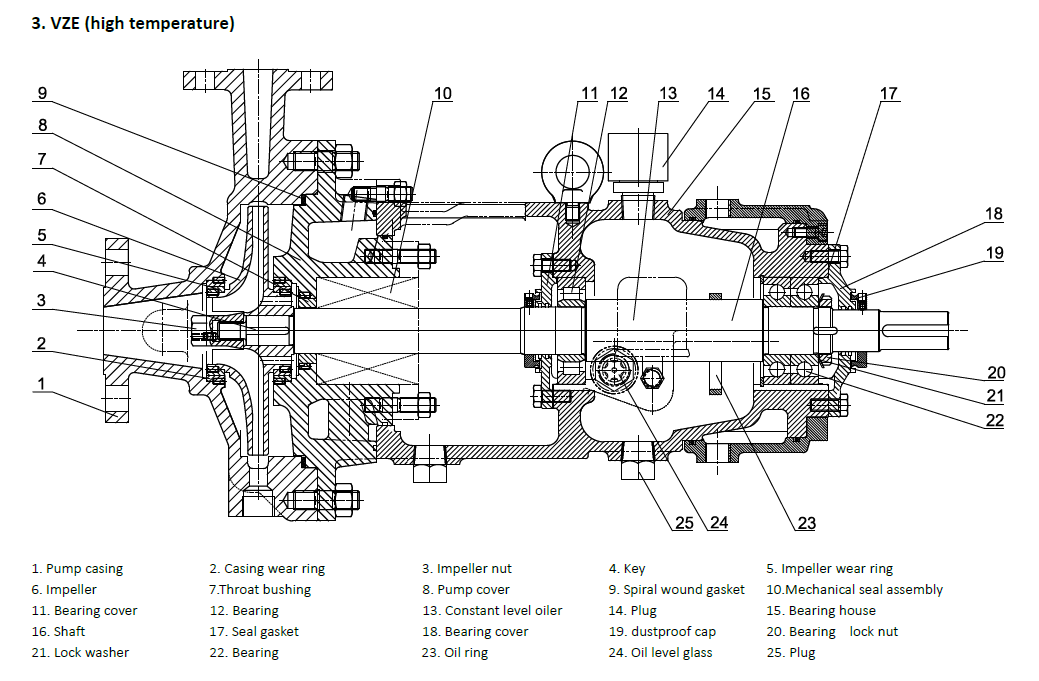

Cross Section Drawings

VZ Series Family Curves

Next Page

Next Page

Related Products