PL Series ELECTRIC CANNED MOTOR PUMP

V-FLO electric canned motor pumps are the optimized design output from the state-of-art technology in combination with years of research results for canned motor pumps utilized in critical applications such as nuclear power plants, military warships.

Product Description

Overview

V-FLO electric canned motor pumps are the optimized design output from the state-of-art technology in combination with years of research results for canned motor pumps utilized in critical applications such as nuclear power plants, military warships.

Canned motor pump design, fabrication and test follow but not limited to the following standards and codes: GB / T755, GB / T1032, GB / T3216, API685, JB6216 and so on.

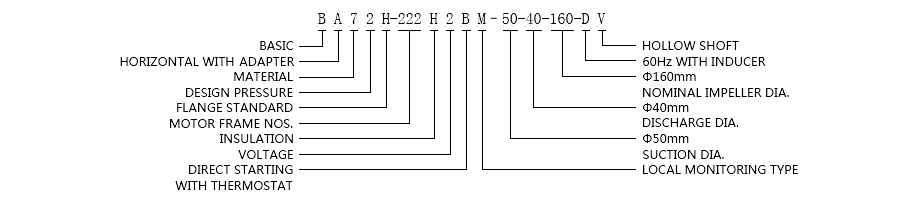

Symbol Description

|

1. Type Definitions a. Types B Basic N Reverse Circulation G High-Temp Insulation Z Sele-Priming R Full-Steam-Jacket V Slurry Seal J Gas-Sealed Slurry K Gas-Sealed Slurry T Special Execution b. Adapter No Mark Without Adapter A Horizontal With Adapter V Vertical Motor-Top With Adapter P Vertical Pump-Top With Adapter W VerticalL Motor-Top Without Adapter Q Vertical Pump-Top Without Adapter c. Materials Material selections follow API standard, including but not limited to the following: 1 HT 2 CS 3 SS304(OCr19Ni9) 4 SS304L(OCr19Ni11) 5 SS316(OCr17Ni12Mo2) 6 SS316L(OCr17Ni14Mo2) 8 SPECIAL d. Design Pressure 1 1.0 Mpa 2 2.0 MPa 3 3.0 MPa 4 4.0 MPa 5 5.0 MPa 6 6.0 MPa e. Flange Standard No Mark JIS H HG A ANSI G GB S SH T Other |

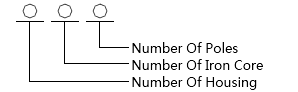

2. Motor a. Motor Frame Nos

b. Insulation F Class F H Class H J Class H With Cooling Jacket S Class H With Heating Jacket C Class C X Super Heat-Resistant Motor Y Super Heat-Resistant Motor With Heating Jacket Q Super Heat-Resistant Motor With Cooling Jacket Z Other c. Power Supply Voltage No Mark 380V(400V) 2 220V (200V) 9 SPECIAL 6 600V d. Thermostat No Mark Direct Starting Without Thermostat B Direct Starting With Thermostat (Close Contact) E Y-Starting With Thermostat C Y-Starting Without Thermostat D Direct Starting With Thermostat (Open Contact) e. Bearing Monitor No Mark No M Local Monitoring K Remote Panel-Mount G Protection Box B Alarming Device (Local Monitoring ) U Alarming Device ( Remote Monitoring ) Z OTHER f. Bearing Materials No Mark Carbon Graphite S Ptfe T Sic W Hard Carbon Graphite Of A Super Class |

|

3. Pump a. Suction Dia. b. Discharge Dia. c. Nominal Impeller Dia. d. Impeller Types No Mark Standard A Radial Blade T Special e. Stage No Mark Single 2 2 3 3 4 4 5 5 6 6 7 7 8 8 9 9 10 10 f. Jacket No Mark None J Semi-Jacket (COOLING) S Semi-Jacket (Heating) K Full-Jacket (Heating) |

4. Additional a. Inducer No Mark 50Hz No D 60Hz No F 50Hz Yes E 60Hz Yes b. Circulation Structure C - With Cooler J - With Jacket (Cooling) S - With Jacket (Heating) V - Hollow Shaft B - Back Flushing M - Single - Pipe Coil Heat Exchanger T - Tubebank Heat Exchanger Y - Other Heat Exchanger |

Model identification

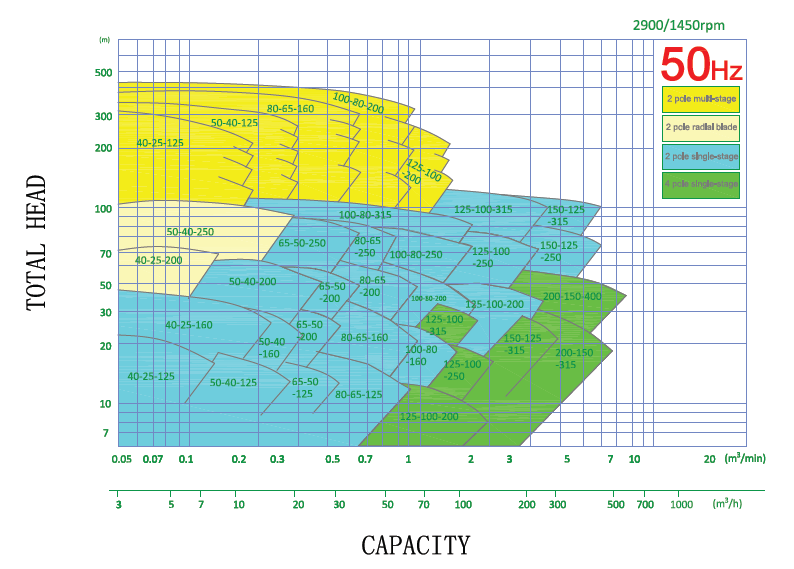

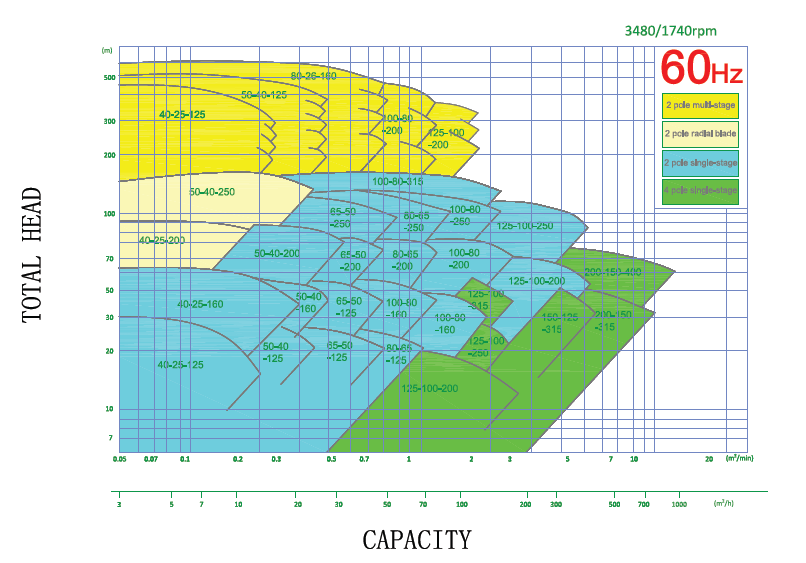

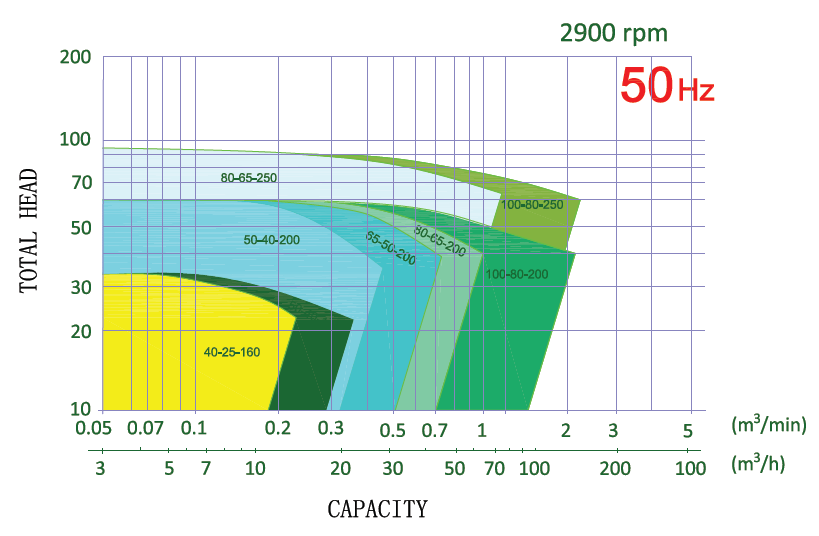

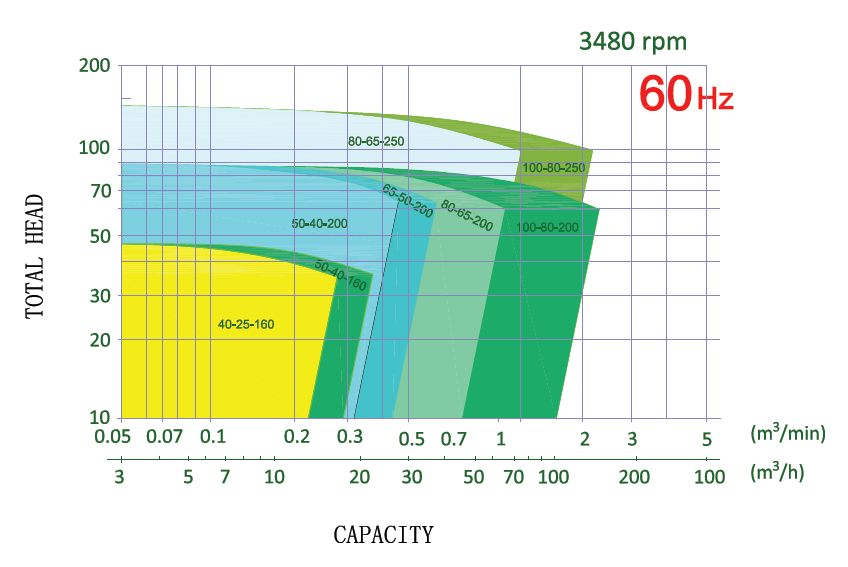

Family Curves

Previous Page

Related Products

download