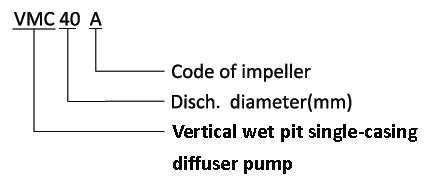

VMC Series VERTICAL WET PIT SINGLE-CASING DIFFUSER PUMP

VMC series vertical wet pit single-casing diffuser pumps are API VS1 pumps designed and manufactured completely in accordance with API610 11 the Edition.

Product Description

Overview

VMC series vertical wet pit single-casing diffuser pumps are API VS1 pumps designed and manufactured completely in accordance with API610 11 the Edition.

First stage impeller of VMC pump is a suction impeller located at the bottom of pump to meet severe cavitation performance requirements. A balancing drum is equipped on to balance the axial thrust while the residue thrust is balanced by a pair of angular contact ball bearings lubricated with oil in the bearing housing. Bearing housing has an independent internal circulating automatic lubricating system, improving the service life of bearings. Hydrodynamic radial sleeve bearings is located at the entrance of pump and in the middle pipeline, which is lubricated by pumped medium. Pump installation depth is determined by its NPSH requirements and intermediate supporting structure may be required when it comes to a certain depth.

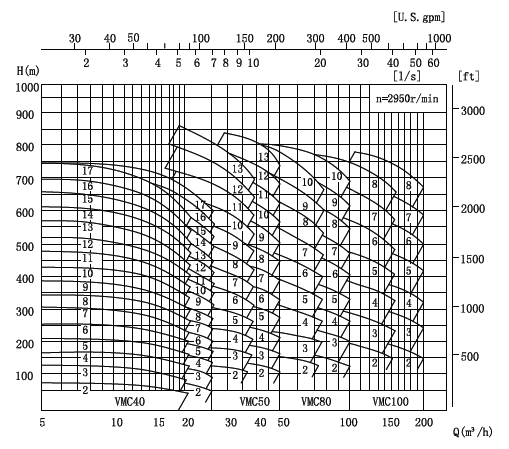

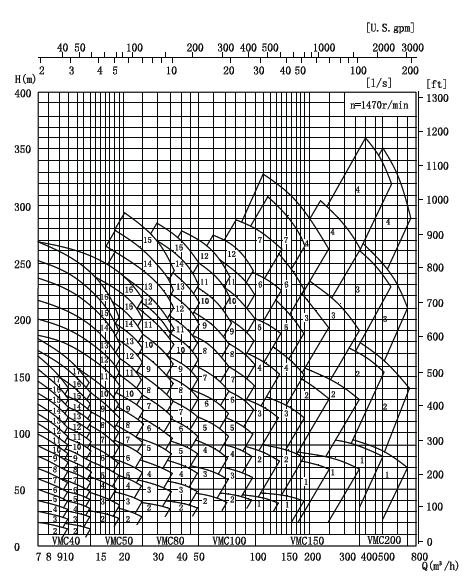

Performance Range

Discharge (DN): 40 ~ 200mm

Flow rate (Q) : ~ 800m3/h

Disch. head (H): ~ 800m

Working pressure (P): ~ 10MPa

Working temperature (t) : -20℃ ~ 120℃

Speed (n): 1470 or 2950r/min

Model Description

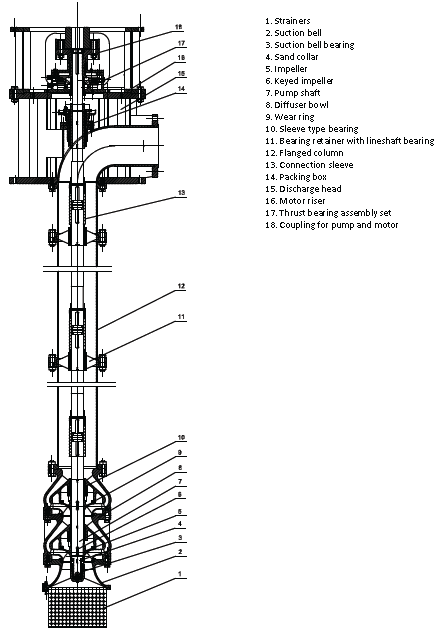

Pump Structure

VMC series are vertical wet pit single-casing diffuser pumps, which is carefully analyzed and specially developed on the basis of the extensive study of structural features of foreign and domestic pumps of its kind. They are typically applied to liquid delivery in petrochemical engineering and effluent oil treatment.

1. Pump Casing and Column Pipes

VMC series are multi-stage submerged pumps with pump casing installed inside the liquid of media pool and the installation depth is to be determined by the system NPSH and pump NPSHr so as to avoid cavitation in the worst case.

Column pipes meet the requirements of pumping media with an intermediate guide bearing between two pipes and each section of the pipe shall meet API610 standard so as to ensure the maximum allowable continuous speed is lower than the 1st critical speed. In combination with rigid shaft design, pump operation stability and limited vibration can be guaranteed to the greatest extent.

2. Impeller and Diffuser

The first stage impeller is normally designed as a suction impeller to improve the cavitation performance.

Each type of pump has several groups of corresponding impellers and diffusers to guarantee stable performance, high efficiency and low NPSHr under different operating conditions.

3. Sealing System

It is of API682 cartridge mechanical seal design with configurable single mechanical seal, tandem type double mechanical seal and parallel type double mechanical seal. Throttle bushing components are adopted to lower the pressure of mechanical seal

chamber, which is able to be equipped with different flushing & cooling systems according to different pumping media.

4. Bearing Housing & Lubrication

Angular contact ball bearing in pairs are adopted to bear residue thrust force and rotor weight.

Large oil chamber of bearing housing is equipped with independent inner circulating automatic lubricating system, which is able to effectively lubricate bearing with uniform temperature and guaranteed long life service.

Cooling equipment is adopted to lower oil chamber temperature while pumping high temperature media.

Oil chamber is designed with large oil capacity.

Constant oil cup is able to make on-line compensation of lubricating oil and oil gauge is able to detect oil level in real time.

The bearing parts can be disassembled entirely for easy maintenance.

Cross Section Drawings

|

|

VMC Series Family Curves

|

|

Previous Page

Next Page

Previous Page

Next Page

Related Products