VTMC Series DOUBLE-CASING VERTICAL DIFFUSER PUMP

VTMC series are double-casing vertical diffuser pumps designed and manufactured completely in accordance with VS6 API 610 11th Edition.

Product Description

Overview

VTMC series are double-casing vertical diffuser pumps designed and manufactured completely in accordance with VS6 API 610 11th Edition. It is designed for applications in industrial process, chemical industry, petrochemical industry, petroleum processing, petroleum & natural gas and petroleum refining where NPSH requirements are extremely demanding and important. It is also widely used in cryoengineering.

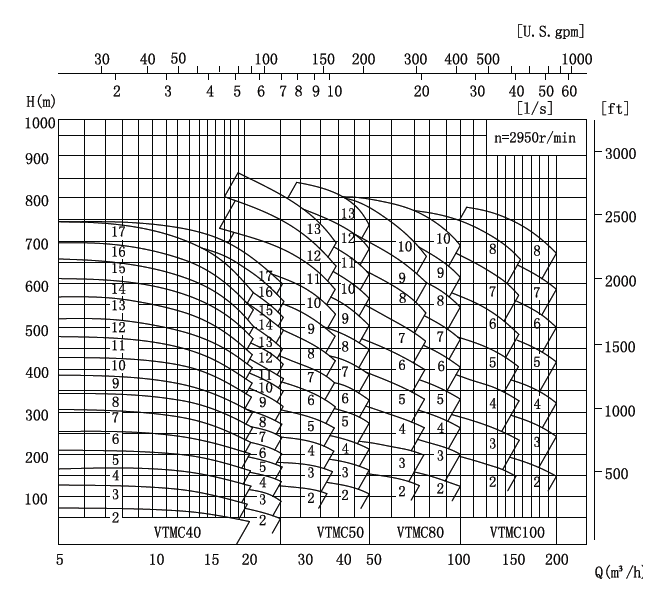

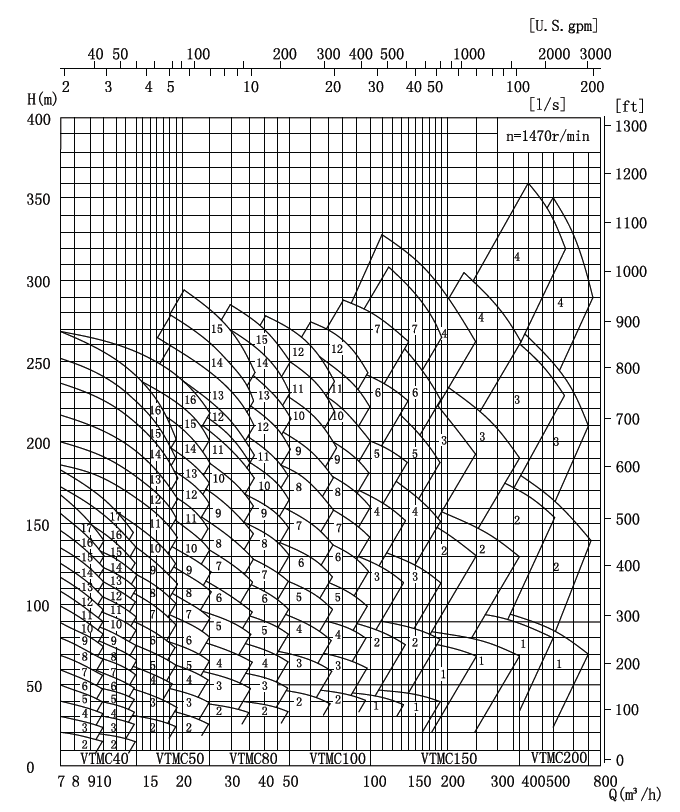

Performance Range

Discharge Size: DN = 40 ~ 200mm

Flow rate: Q = 1700m³/h

Head: H = 800m

Working pressur e: P = 10Mpa

Working temperature: T = -180℃~180℃

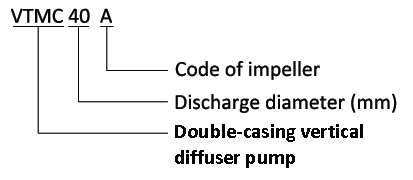

Model Description

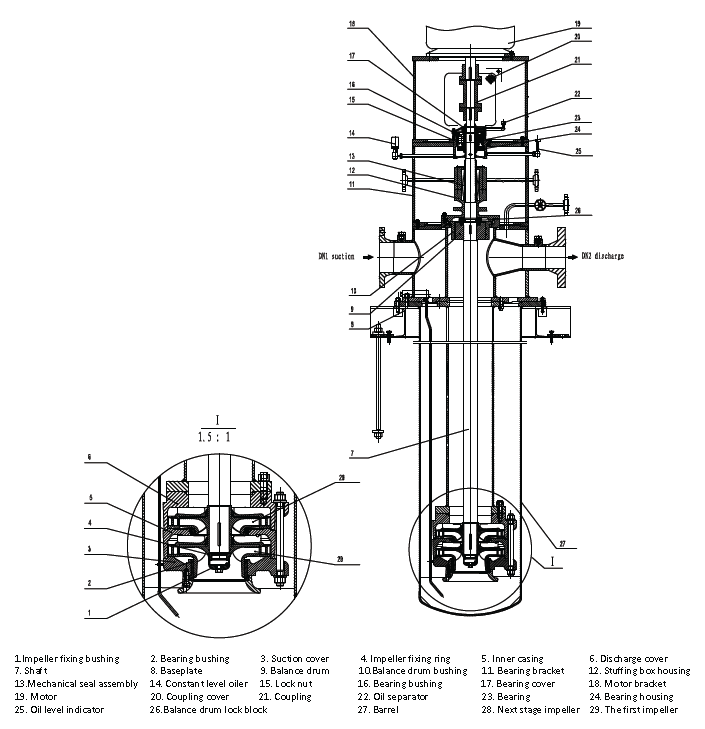

Pump Structure

VTMC series double-casing vertical diffuser pumps are optimized output on the basis of extensive study and careful analysis on the structural features and performances of existing designs available in the markets, focusing on the applications for liquid transferring requirements in petrochemical engineering, sewage & effluent oil treatment.

The first stage is a suction impeller specially designed for low NPSH working condition.

Rotor is dynamically balanced for stable operation.

1. Pump Casing & Column Pipes

VTMC series as a double-casing vertical diffuser pump, the pump length and installation depth can be designed according to the process and installation requirement for NPSH.

It can be installed as submerged on top of the media pool without outer casing, or installed on open or pressurized vessel.

Inline installation with standard horizontal arrangement. It is also possible to connect the pipeline with suction flange at bottom of the pump after removing outer casing.

The design and structure of column pipes shall suit the need of pumped media and a guide bearing shall be equipped between two column pipes designed as per API 610 to guarantee the Max. allowable continuous speed within the limit of 1st critical speed of the rigid shaft so as to ensure stable operation with less vibration.

2. Impeller and Guide Vane

The first stage impeller is generally a suction impeller to improve cavitation performance. Each type of pump has several groups of impellers and diffuser design applicable for different operating requirements with stable performance, high efficiency and low NPSHr.

3. Sealing System

API682 cartridge mechanical seal can be single mechanical seal, tandem type double mechanical seal and parallel double mechanical seal. Throat bushing assembly is employed to reduce the pressure inside the mechanical seal chamber. Different bushing and cooling system can be equipped according to pumped media.

4. Bearing Housing and Lubrication

Angular contact ball bearings are used to balance residual thrust force and rotor weight.

Large oil storage in bearing housing is equipped with independent automatic circulating system to ensure effective lubrication.

External water or air cooling shall be installed for high temperature pumped media.

Oil chamber is designed with enhanced capacity.

Constant level oiler is installed for online filing and indication of oil level at real time.

Bearing assembly is designed for quick dismantling and easy maintenance.

5. Balancing Device

Balance drum is used to balance thrust force.

A pipeline connected with back end of balancing drum further reduces the pressure of mechanical seal chamber.

Cross Section Drawing

VTMC Series Family Curves

Previous Page

Previous Page

Related Products